Service hotline

+86 0755-23615795

Release date:2025-07-24Author source:KinghelmViews:117

In the rapidly evolving landscape of consumer electronics, the demand for advanced wire to board connector solutions has surged. Procurement and engineering teams now face the critical challenge of selecting connectors that combine high reliability, compact design, and efficient manufacturing compatibility. This comprehensive article explores the latest trends that shape the future of the wire to board connector market, aiming to provide actionable insights for professionals striving to enhance product performance while optimizing costs.

Today’s consumer electronics require compact, durable, and high-performance wire to board connector systems. Companies must ensure seamless integration of connectors into sophisticated devices, all while managing thermal issues and mechanical stress. **Advanced materials**, innovative locking mechanisms, and miniaturized designs have become central to achieving these objectives. As demand rises for smaller devices with more features, procurement and engineering teams must stay ahead by understanding these breakthroughs.

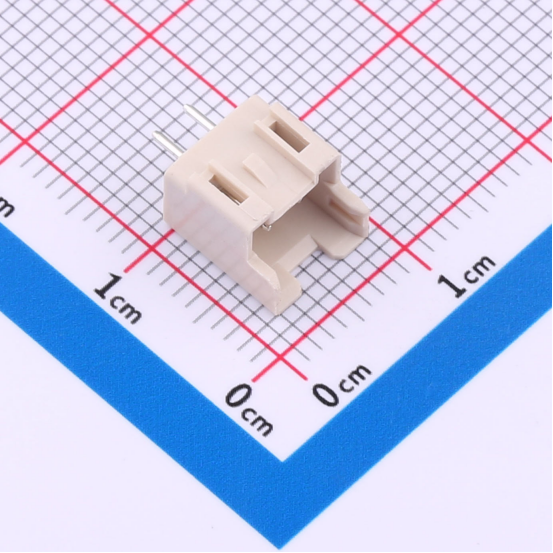

The trend towards **smaller, thinner** devices drives the industry to adopt **high-density** wire to board connector solutions. Manufacturers now produce connectors with extremely fine pitches, often below 1.0 mm. These solutions help designers maximize PCB real estate while supporting complex functions. Additionally, **low-profile** connectors minimize z-height, crucial for smartphones, wearables, and ultrabooks. Such developments enable brands to deliver feature-rich, lightweight products that consumers demand.

These factors help maintain performance without sacrificing reliability in space-constrained designs.

As devices integrate more advanced functions, **power demand** rises. Modern wire to board connector solutions now handle higher currents, sometimes exceeding 10 A, while keeping heat generation low. This is achieved by using **copper alloy contacts**, gold plating, and improved thermal management. Efficient connectors contribute directly to longer battery life, better performance, and reduced thermal stress.

Leading brands have shifted towards high-performance **plastics** and conductive alloys, balancing electrical performance and mechanical robustness. These improvements also help products meet increasingly strict environmental regulations.

Consumer electronics face mechanical shocks, moisture, and temperature fluctuations. Modern wire to board connector solutions use advanced sealing techniques, corrosion-resistant materials, and robust housing designs to enhance durability. This is essential for devices like smartwatches, fitness trackers, and portable medical devices, which must perform reliably outdoors and under constant movement.

Compliance with **international standards** like IPC and UL further reassures procurement teams of connector quality.

Mass production demands connectors suitable for **automated insertion and soldering**. Modern wire to board connector systems feature symmetrical designs, guiding features, and standardized pin layouts to improve assembly yield. This reduces manual labor, shortens production cycles, and ensures consistent quality.

Choosing connectors optimized for automation not only cuts costs but also enhances reliability by reducing human error. This aligns with lean manufacturing and Industry 4.0 principles, supporting smarter and more efficient factories.

With rising environmental concerns, **eco-friendly** wire to board connector materials gain traction. Suppliers now provide halogen-free plastics and recyclable metals, meeting global regulations like RoHS and REACH. Engineering teams must evaluate material choices not only for performance but also for end-of-life recycling and environmental footprint.

Sustainability becomes a competitive advantage as consumers and partners demand greener products. **Responsible sourcing** and transparent supply chains help brands build trust and market differentiation.

Next-generation consumer electronics will push connectors towards even greater **miniaturization**, **higher data rates**, and **better thermal performance**. Wireless charging, AR/VR devices, and AI-powered gadgets will demand new connector solutions supporting faster communication and smarter integration.

These innovations will reshape product design, enabling sleeker devices and enhanced user experiences.

By understanding these trends in wire to board connector technology, procurement and engineering teams can:

Ultimately, staying informed about wire to board connector innovations empowers teams to develop competitive, reliable, and eco-friendly products that resonate with modern consumers.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853