Service hotline

+86 0755-23615795

Release date:2025-07-29Author source:KinghelmViews:163

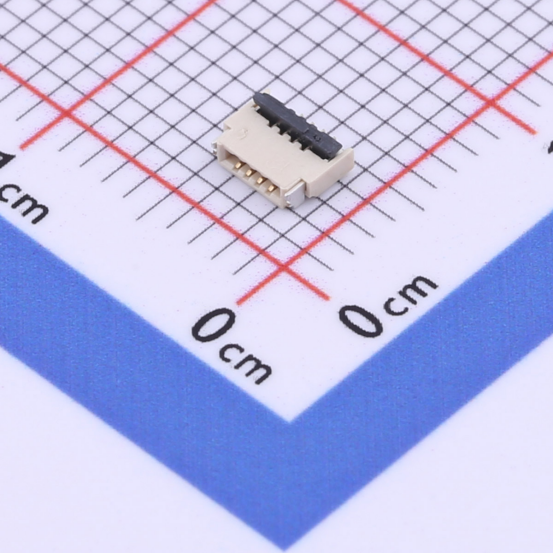

In today’s dynamic consumer electronics sector, selecting a reliable FPC connector manufacturer is crucial. Procurement and engineering teams face challenges balancing technical performance, cost, and long-term reliability. This comprehensive article will guide you through essential criteria and professional strategies to ensure you choose the most suitable FPC connector partner for your projects.

When it comes to flexible printed circuit (FPC) assemblies, the quality of the FPC connector plays a decisive role in product performance. Poor-quality connectors can lead to signal loss, mechanical failure, and increased warranty claims. A trusted FPC connector supplier provides consistency, compliance with international standards, and technical expertise, all of which are vital for successful product launches and brand reputation.

One of the first steps in selecting an FPC connector manufacturer is examining their production capabilities. Companies should:

Reliable FPC connector producers typically invest heavily in automated equipment and skilled engineers. These factors ensure repeatable quality, reduced defect rates, and faster turnaround for design iterations.

Consumer electronics designs often demand unique configurations. Selecting a manufacturer with robust engineering support is critical. Look for a supplier offering:

Customization is especially valuable for thin, compact products where standard solutions may not suffice. Choosing a manufacturer that understands advanced material science, precise molding, and complex assembly techniques helps ensure long-term reliability.

Uninterrupted supply is essential for electronics brands operating globally. It’s wise to select an FPC connector manufacturer that:

These factors protect your projects from delays, sudden price hikes, and quality fluctuations, ensuring steady growth in competitive markets.

Investigate a potential manufacturer’s track record. Reputable FPC connector suppliers openly share success stories, client testimonials, and case studies. Procurement teams can also:

Transparency and a strong reputation often indicate consistent performance and ethical business practices.

Even the highest-quality FPC connector products occasionally face unforeseen challenges. A manufacturer’s commitment to post-sale support shows their confidence in product durability. Leading suppliers provide:

This partnership approach reduces risk and ensures smooth integration into your assembly lines.

The electronics industry evolves quickly, and so should your FPC connector supplier. Evaluate whether the manufacturer invests in R&D, introduces new materials, or offers cutting-edge features such as:

Innovation-driven suppliers enable your teams to build competitive, future-ready products.

Beyond unit price, consider the complete financial impact. Reliable manufacturers may appear costlier initially but often deliver:

Total cost of ownership often outweighs immediate price savings, supporting long-term profitability.

Choosing a reliable FPC connector manufacturer requires careful analysis of technical capability, supply chain resilience, innovation, and after-sales support. For procurement and engineering teams, partnering with the right supplier safeguards product quality and brand reputation while driving future growth.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853