Service hotline

+86 0755-23615795

Release date:2025-08-05Author source:KinghelmViews:216

In Bluetooth hardware design, the PCB footprint is the “invisible cornerstone” that determines antenna performance. Even with the same Bluetooth module, poor PCB footprint design—such as a 0.2 mm pad misalignment or missing ground plane—can cause signal strength to plummet from -55 dBm to -85 dBm, reducing transmission range by over 60%. This article systematically explains the core design factors, common types, and practical techniques for Bluetooth antenna PCB footprints, helping hardware engineers avoid 90% of design pitfalls.

Bluetooth operates in the 2.4 GHz band (λ ≈ 12.5 cm), and antenna dimensions must be proportionate to the wavelength:

Monopole antennas: Length ≈ λ/4 (≈3.1 cm); width adjusted for impedance (typically 1–3 mm)

Inverted-F antennas (PIFA): Total height ≈ λ/8 (~1.5 cm), radiator arm ≈ λ/4 (tolerance ≤0.5 mm to prevent ±20 MHz frequency shift)

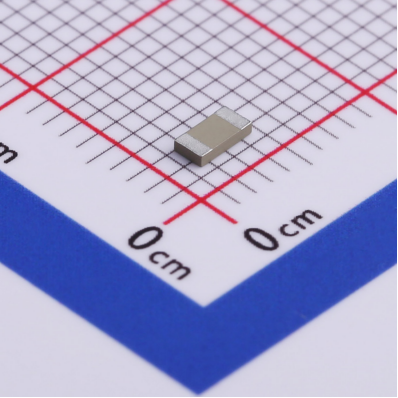

Chip antennas: Side length ≈ λ / (2√εr) (εr = dielectric constant; e.g., FR4 εr = 4.4 → ~1.8 cm)

Design note: A 0.1 mm size deviation can shift center frequency by 5–8 MHz. Calibration via simulation tools like HFSS is recommended.

Pad Parameters:

Feed pad diameter: 0.8–1.2 mm (fits 0.3 mm solder wire); spacing to RF output pad ≤0.5 mm to minimize parasitic inductance

Ground pad area ≥5× the feed pad (e.g., 1 mm² feed pad → ≥5 mm² ground pad) to ensure ground resistance <0.05Ω

Feedline Design:

Use 50Ω microstrip (on FR4: width ≈ 0.9 mm); length ≤5 mm (every extra 1 mm = ~0.1 dB signal loss)

Avoid sharp corners (use 45° or curved traces); right-angle bends may introduce impedance mismatch up to 10Ω

Keep ideal ground-plane spacing relative to the antenna:

Chip antenna: Edge of ground plane ≥3 mm from radiator edge (prevents edge-field interference)

PIFA: Ground plane beneath antenna should be ≥2× antenna area (e.g., 10×10 mm antenna → ≥20×20 mm ground)

Ground plane integrity:

Avoid cutouts or high-speed signals (e.g., USB traces) under the antenna, as these disrupt ground continuity and can raise VSWR from 1.2 to 2.5.

FR4: Low-cost (~$1.50/board), suitable for consumer devices (e.g., Bluetooth speakers); needs margin in layout due to dielectric variation (±2% with temperature)

Ceramic: High εr (20–90), enabling 40% smaller footprints; brittle, suitable for precision devices (e.g., medical sensors), with 0.5 mm edge clearance recommended

FPC substrates (e.g., LCP): εr ≈ 3.0; flexible, bendable (min. bend radius ~1 mm), ideal for wearables; use ≥1 oz copper for robust feedline

Structure: Rectangular copper radiator (e.g., 15×10 mm), edge-fed, ground layer underneath

Performance: Gain 0–2 dBi, bandwidth ≥80 MHz (covers 2.4–2.48 GHz), suitable for BLE devices (e.g., fitness bands)

Design Tip: Add 0.2 mm “tuning stubs” to radiator edges; trimming 0.1 mm raises frequency ~3 MHz

Structure: Radiator arm (λ/4) + shorting pin to ground + feedline; total height ≤5 mm (good for slim devices)

Advantages: Less affected by metal housing (30% better anti-interference than chip antenna); suited for earbuds, smartwatches

Critical Dimension: Distance between feed and shorting pin: 2–3 mm (affects impedance; every 0.1 mm increase = +2Ω)

Structure: Slender radiator (λ/4), grounded at base, simple layout with no complex ground plane

Performance: Gain 1–3 dBi; 20% longer range than chip antenna in same environment; ideal for Bluetooth gateways

Layout Tip: Keep a 20 mm metal-free zone around radiator (to prevent distorted radiation pattern; up to -15 dB in affected directions)

Identify Bluetooth type: Classic Bluetooth (requires EDR and wider bandwidth) vs BLE (low power, narrower bandwidth)

Set performance goals: e.g., RSSI ≥ -75 dBm at 10 meters, VSWR ≤ 1.5, bandwidth ≥85 MHz

Choose substrate: Based on thickness (<3 mm → ceramic) and cost (mass production → FR4)

Use Altium Designer or KiCad for footprint drawing:

Radiator dimensions via λ/4 formula (accounting for εr)

Feedline width for 50Ω (e.g., FR4 with 1.6 mm thickness → ~1.2 mm line width)

Ground-to-radiator spacing ≥5 mm to reduce coupling

Import model into simulation tools (e.g., CST, ADS), test:

Return Loss (S11): ≤ -10 dB across 2.4–2.485 GHz

Radiation Pattern: For omnidirectional antennas, horizontal gain variation ≤3 dB

Impedance: 50Ω ±5Ω; outside range → adjust feedline width or add matching caps

Create 3–5 test boards with slight tuning variations (e.g., radiator ±0.3 mm)

Measure S-parameters with network analyzer:

Center frequency offset >10 MHz → trim radiator (long → shorten; short → extend)

Impedance mismatch (e.g., 65Ω) → add 1pF capacitor in series (reduces ~10Ω)

Validate dielectric variation between FR4 batches (±0.2 in εr); reserve 0.5 mm tuning margin

Adjust solder mask design:

No solder mask over radiator surface (to reduce εr variation)

Open window on pad area (for better solderability)

|

Issue |

Root Cause |

Solution |

|

Center frequency shift (e.g., 2.42 → 2.46 GHz) |

Radiator too short (e.g., designed 31 mm → actual 30.5 mm) |

Extend radiator by 0.5 mm (every +0.1 mm lowers frequency ~5 MHz) |

|

Impedance too high (e.g., 60Ω) |

Feedline too narrow (designed 0.8 mm → made 0.6 mm) |

Widen to 1.0 mm (each +0.1 mm width reduces ~3Ω) |

|

Distorted radiation pattern |

Ground plane too small (<2× radiator) |

Expand ground to 3× radiator area; round corners |

|

Poor batch consistency |

Dielectric constant fluctuations |

Use high-stability substrate (e.g., ceramic) or add compensation circuits |

The essence of Bluetooth antenna PCB footprint design lies in precise sizing, impedance matching, and proper grounding. Always consider Bluetooth type (Classic/BLE), device form factor (metal/plastic housing), and substrate properties. Use simulations to reduce trial cost. Remember: a 0.1 mm dimension error can cause a 10 dB signal difference, while a well-designed ground plane can improve radiation efficiency by over 40%.

Need a custom footprint design for specific devices (e.g., TWS earbuds, IoT sensors)? Provide your 3D model and performance targets to receive a tailored PCB footprint solution—including layout files and simulation data.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853