Service hotline

+86 0755-23615795

Release date:2025-08-11Author source:KinghelmViews:141

In the field of electronic connectors, pin headers serve as core components enabling PCB-level interconnections, with their performance directly determining the reliability of electronic systems. This article focuses on the Kinghelm KH-2.54PH180-2X30P-L11.5 industrial-grade pin header, exploring its innovative design and industry applications to reveal why it is an ideal choice for high-end electronic equipment.

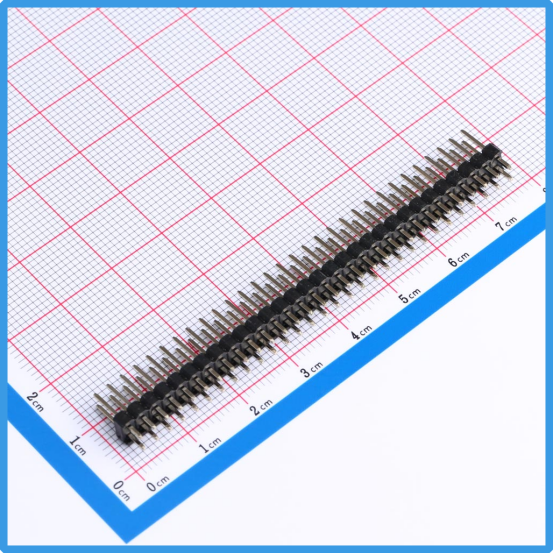

Kinghelm KH-2.54PH180-2X30P-L11.5 Product Image

1. Core Product Highlights

1. Dual-Row 60PIN High-Density Design

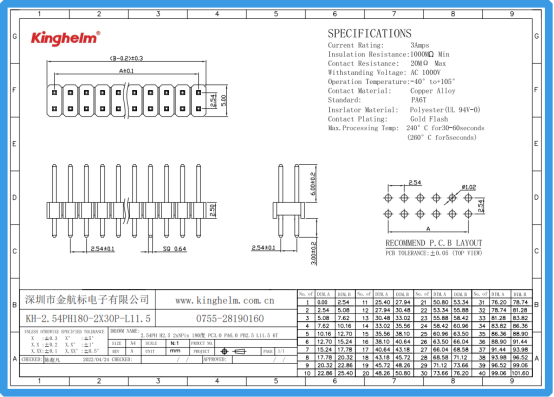

This product adopts a 2×30P dual-row structure, delivering 60 contact points within a compact 25.4mm × 11.5mm footprint. Compared to traditional single-row pin headers, contact density is increased by 100%, making it particularly suitable for complex circuit systems requiring multi-signal transmission. The standard 2.54mm pitch ensures compatibility with mainstream PCB hole spacing while allowing space for manual soldering operations.

2. Triple Electrical Protection System

3A continuous current capacity – Gold-plated copper alloy contacts with 0.76μm plating thickness ensure low temperature rise under high-current transmission.

AC1000V withstand voltage – The insulating housing is made of modified PBT material with a dielectric strength of 15kV/mm, effectively resisting transient voltage surges.

≤20mΩ contact resistance – Precision stamping processes optimize contact geometry, significantly reducing signal attenuation.

3. Industrial-Grade Environmental Adaptability

Wide temperature range of -40℃ to +105℃ – UL94V-0 certified encapsulation material maintains structural stability in high-temperature environments such as automotive engine bays.

Salt spray resistance: no corrosion after 72 hours – Composite plating technology exceeds MIL-STD-1344 [敏感词] standard requirements.

1000MΩ insulation resistance – Specially designed insulating rib structures effectively prevent leakage between adjacent contacts.

2. Differentiated Competitive Advantages

1. Structural Innovation

The 11.5mm pin length is optimized through fluid dynamics simulation to ensure uniform solder flow during wave soldering, achieving solder joint tensile strength above 70N. Compared to common 8mm pin products, soldering reliability is improved by 40%.

2. Manufacturing Process

With a 16-step quality control process, critical stages such as contact forming, electroplating, and dimensional inspection are fully automated. Each production batch undergoes:

Contact resistance test (≤20mΩ)

Withstand voltage test (AC1000V / 1 minute)

Temperature shock test (-40℃ to +125℃, 100 cycles)

3. Certification System

Certified to CE, RoHS, and REACH standards, and compliant with IPC-620 requirements. A specially designed anti-misplug mechanism with both color markings and mechanical keying reduces assembly errors.

3. Typical Application Scenarios

1. New Energy Vehicle BMS Systems

In Battery Management Systems (BMS), this pin header ensures reliable connections between the main control board and acquisition boards. The 60PIN high-density design supports simultaneous transmission of battery voltage, temperature, and balancing control signals, while the 3A current capacity meets fast-charging demands.

2. Industrial IoT Gateways

Used to connect the main processor module to wireless communication modules (e.g., 4G/5G), the dual-row structure effectively separates power and signal lines, while the 1000V withstand voltage ensures electrical safety in industrial environments.

3. Medical Imaging Equipment

In control units of CT and MRI systems, the low contact resistance ensures high-speed signal integrity, and the -40℃ to +105℃ temperature range suits diverse cooling conditions between system modules.

4. Alignment with Industry Trends

1. Miniaturization & High Density

As 5G base stations and servers demand greater space efficiency, the 2.54mm pitch design strikes the perfect balance between universality and integration.

2. Functional Integration

The product reserves an EMI shielding mounting position, enabling future versions to integrate electromagnetic interference protection. This modular approach aligns with system-level integration needs in automotive and aerospace sectors.

3. Smart Manufacturing Compatibility

Dimensional tolerances are controlled within ±0.05mm, enabling compatibility with automated placement equipment. A specially designed pick-and-place surface ensures seamless integration with SMT line vacuum nozzles.

Kinghelm KH-2.54PH180-2X30P-L11.5 Specification

5. Selection Guide

Current requirement evaluation – Confirm total current ≤ 3A × number of pins, with a recommended 20% safety margin.

Space layout verification – Use 3D modeling software to simulate PCB mounting, paying attention to pin length and PCB layer thickness compatibility.

Environmental adaptability – For high-temperature, high-humidity, or dusty environments, prioritize products tested to MIL-STD-202 standards.

Brand assurance – Leading manufacturers such as Kinghelm provide complete DFM (Design for Manufacturability) support, shortening product development cycles.

Through this deep-dive analysis, it is clear that the Kinghelm KH-2.54PH180-2X30P-L11.5 pin header—thanks to its innovative structural design, rigorous quality control, and broad environmental adaptability—offers significant advantages in high-end electronics. As smart manufacturing continues to advance, such industrial-grade connectors that combine performance and reliability will become the foundation for building complex electronic systems.

About Kinghelm

Shenzhen Kinghelm Electronics Co., Ltd.(www.kinghelm.net)has technical backbones from Tsinghua University and UESTC, and has introduced overseas returnee professionals. Kinghelm is able to develop highly reliable and high-performance antenna and connector products.KH series products of "Kinghelm" brand include Beidou/GPS antennas, RF adapter connectors, plug connector, electrical data connectors, terminals, and customized vehicle harnesses, industrial / medical connectors, and special antenna connectors."Kinghelm connects world", Kinghelm has grown with the development of China's Beidou industry. Starting from supplying Beidou/GPS dual mode antennas, IPEX terminals, and RF adapter cables for automotive manufacturers, Kinghelm has continuously developed products. Currently, it has a series of WiFi, Bluetooth, NB-loT, LoRa, Zigbee, UWB, and GSM antennas, RFID tags, RF adapter cables, standard microwave antennas, vehicle grade SMA, SMB, FAKRA holders, coaxial cables, and can customize non-standard antenna connectors based on customer drawings or samples.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853