Service hotline

+86 0755-23615795

Release date:2025-07-29Author source:KinghelmViews:190

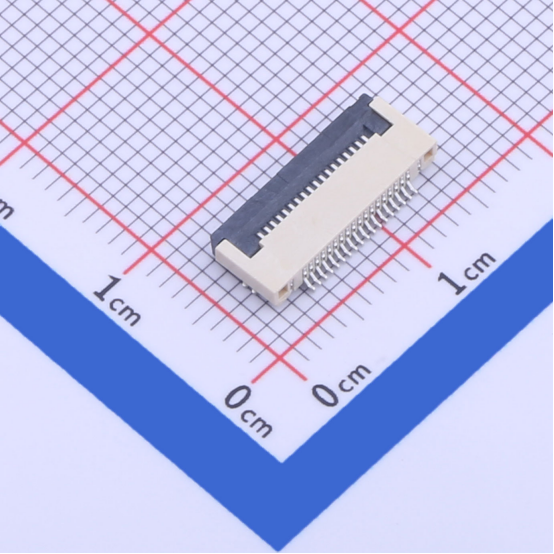

In the competitive world of consumer electronics, selecting the correct FPC connector for PCB applications is critical. Procurement and engineering teams must navigate complex technical choices and supplier options. This guide offers professional insights to ensure that your next project benefits from reliable and high-performance FPC connector solutions, aligning product design with market demands.

The role of an FPC connector extends far beyond connecting flexible printed circuits. In a PCB design, the right FPC connector ensures mechanical stability, signal integrity, and long-term reliability. Choosing poorly can result in design failures, increased costs, and customer dissatisfaction. For consumer electronics brands, precision and supplier quality make the difference between success and failure.

Procurement and engineering teams need to evaluate several points before finalizing a connector design:

Aligning these factors with your PCB requirements ensures performance and durability, supporting market competitiveness and reducing production issues.

Beyond technical details, choosing a reliable FPC connector supplier plays a strategic role. Procurement teams should evaluate suppliers on:

Reliable manufacturers help avoid delays and unexpected costs, ensuring that your product launches remain on schedule and meet quality targets.

Modern consumer electronics often require custom FPC connector solutions. Engineering teams should work with manufacturers offering:

Custom solutions align with advanced product designs, from foldable devices to ultra-thin tablets. A supplier with strong R&D can translate ideas into robust prototypes and mass production models quickly.

High-quality FPC connector suppliers invest in automated inspection and rigorous quality testing. Procurement teams should look for manufacturers that provide:

Documented quality assurance helps identify issues early, saving costs and improving brand reputation in competitive markets.

While unit price matters, teams should calculate the total value of an FPC connector choice. Consider factors like:

These benefits can outweigh initial cost savings, especially for high-volume consumer electronics production.

Innovative electronics products rely on cutting-edge FPC connector solutions. Teams should partner with manufacturers that follow market trends and invest in:

This alignment keeps your products competitive and ready for future technological changes.

Top-tier FPC connector manufacturers offer robust after-sales support, including:

After-sales collaboration builds long-term supplier relationships that benefit both procurement and engineering teams.

Finding the right FPC connector for your PCB designs combines technical analysis, supplier evaluation, and market foresight. Teams who invest in thorough research and strong supplier partnerships create durable, high-performance products that delight consumers and strengthen brands.