Service hotline

+86 0755-23615795

Release date:2025-08-05Author source:KinghelmViews:205

In the ongoing design wave of modern electronic devices evolving toward thinner and higher-density forms, the mounting methods and structural innovations of connectors have become decisive factors for product success. Kinghelm Electronics (Kinghelm) has introduced the KH-AF90QCSMT-10JB-H6.3 Type-A Female Right-Angle Horizontal Mount Receptacle Connector, an advanced solution meticulously crafted for space-sensitive devices and automated high-efficiency production demands. This product deeply integrates Surface Mount Technology (SMT) with a horizontal structural design, enhanced by the "JB" version's special performance optimizations. It achieves a triple breakthrough in high-speed data exchange, stable power transmission, and industrial-grade reliability within compact spaces, providing an exceptional connectivity foundation for consumer electronics, portable devices, and embedded systems.

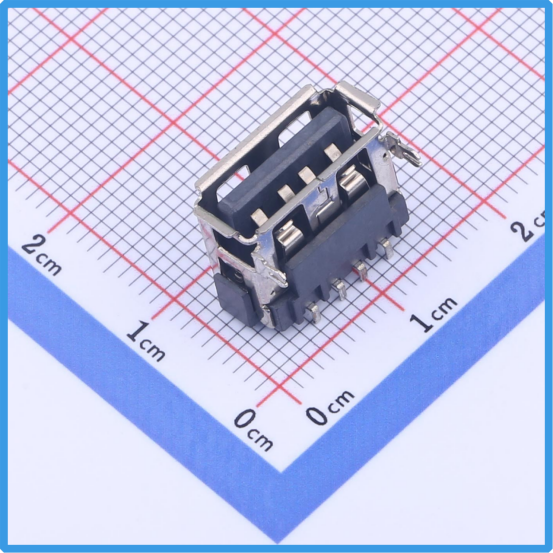

Kinghelm KH-AF90QCSMT-10JB-H6.3 Product Image

The model designation itself is a condensed technical manual. "KH" signifies Kinghelm's brand DNA, representing deep expertise in the connector domain; "AF" defines its standard Type-A Female Receptacle interface form, ensuring seamless compatibility with billions of USB cables and devices worldwide; "90" directly indicates its core mounting feature—90° Right-Angle Horizontal Mount. This design positions the connector body parallel to the PCB surface with the interface perpendicular to the board edge, perfectly freeing Z-axis space—a critical enabler for industrial design in ultra-thin laptops, tablets, and handheld terminals. The "QC" marking suggests its potential support or optimization for Quick Charge protocols, aligning with modern devices' core demand for efficient energy replenishment. "SMT" is undoubtedly the technological focus, declaring its adoption of Surface Mount Technology, the gold standard for modern high-density electronic assembly. "10" likely relates to key dimensional parameters such as interface height or pin configuration. The "JB" suffix continues Kinghelm's premium series lineage, typically indicating deep optimizations such as enhanced plating (e.g., thicker gold layers), material upgrades (high-temp/corrosion-resistant alloys), or structural reinforcement (mechanical stress resistance) to ensure long-term stability in harsh environments. The suffix "H6.3" precisely specifies its mounting height of 6.3mm—a decisive parameter for internal device stacking design, ensuring optimal layout within confined spaces.

The core breakthrough of the KH-AF90QCSMT-10JB-H6.3 lies in its innovative fusion of horizontal mounting structure and SMT process. The right-angle horizontal layout fundamentally revolutionizes the spatial footprint of traditional vertical connectors. When device thickness becomes a core competitive factor, millimeter-level reductions in connector height are critical. This design positions the interface flush against the PCB edge, significantly reducing the overall device profile while optimizing internal airflow and thermal pathways—freeing valuable space for battery expansion, thermal modules, or other functional components. Crucially, the 90° cable exit direction enhances ergonomics, particularly for side-mounted ports on devices, dramatically improving cable insertion/extraction ease and stress distribution rationality, thereby reducing port damage or cable fatigue caused by improper bending.

Its adoption of SMT surface mount technology is synonymous with high-density, high-efficiency manufacturing. Unlike Through-Hole Technology (THT), SMT eliminates the need for PCB through-holes. The connector mounts directly onto surface pads via reflow soldering, achieving robust electrical connections. This process revolution delivers multiple transformative advantages: Firstly, it overcomes dual-sided PCB routing constraints, allowing pads to be distributed across any board area, freeing bottom-layer routing space and enhancing circuit design freedom and signal integrity. Secondly, SMT enables fully automated high-speed placement. Precision pick-and-place systems with optical alignment can assemble thousands of components per minute, significantly boosting production capacity while reducing labor costs. Thirdly, SMT solder joints offer superior high-frequency electrical performance. Shorter lead lengths effectively reduce parasitic inductance and capacitance, which is critical for signal integrity at USB 3.0+ high speeds (5Gbps and beyond). Additionally, SMT's inherent vibration resistance—due to its low center of gravity—greatly enhances connection stability in mobile devices.

The "JB" version's special optimizations form the core guarantee of this connector's reliability. Its contact system typically employs a high-conductivity copper alloy substrate + multi-layer plating structure (e.g., nickel barrier layer topped with thick gold). The nickel layer effectively blocks metal diffusion between the base copper and gold, maintaining contact interface stability. The thick gold layer (typically exceeding 1μm) significantly reduces contact resistance, improves conductive efficiency, and resists corrosion from sulfidation, oxidation, etc., ensuring stable, ultra-low-attenuation electrical contact performance even in humid, salty, or highly polluted industrial environments over extended periods. Structurally, "JB" likely enhances port reinforcement: The metal shell uses phosphor bronze or stainless steel, formed into a high-strength protective frame via precision stamping and riveting to resist physical deformation from frequent mating cycles. Internal insulators employ high-temperature LCP (Liquid Crystal Polymer) or PPS (Polyphenylene Sulfide) engineering plastics, maintaining dimensional stability and insulation strength across a wide temperature range (-40°C to +105°C). For high-speed transmission, it undoubtedly integrates a multi-layer shielding architecture: A full-wrap metal shell provides the first electromagnetic barrier; internal grounding springs achieve low-impedance bonding to the PCB ground plane; differential signal pairs likely adopt coaxial or twisted layouts to suppress crosstalk—ensuring signal purity and eye diagram integrity at 5Gbps speeds to meet stringent USB 3.2 Gen 1 electrical specifications.

Quick Charge support ("QC" marking) highlights its power delivery capability. The connector optimizes power pin current-carrying capacity: Wider pins, high-purity copper materials, and thick plating allow VBUS and GND lines to sustain continuous currents exceeding 3A (with appropriate cables), surpassing basic USB power standards. Combined with the "JB" version's contact reliability assurance, it perfectly adapts to mainstream fast-charging protocols like QC 3.0/4.0 and PD 3.0, delivering efficient energy injection to smartphones, tablets, power banks, etc.—making "50% charge in 30 minutes" a tangible user experience.

This connector's application scenarios precisely target domains where space and performance are equally critical: In ultra-thin consumer electronics, it serves as the core data/charging interface for premium ultrabooks, 2-in-1 tablets, and foldable phones; Portable medical devices (handheld ultrasound, glucose meters, ECG monitors) rely on its compact size and anti-interference capability for reliable data export; Industrial IoT edge devices (HMI interfaces, barcode scanners, handheld data collectors) leverage its vibration resistance for field operation stability; Automotive electronics (in-vehicle infotainment screens, T-BOX, rear-seat entertainment) benefit from its wide-temperature endurance; Smart home hubs (routers, gateways, NAS) require its high-speed transmission to handle home cloud data flows.

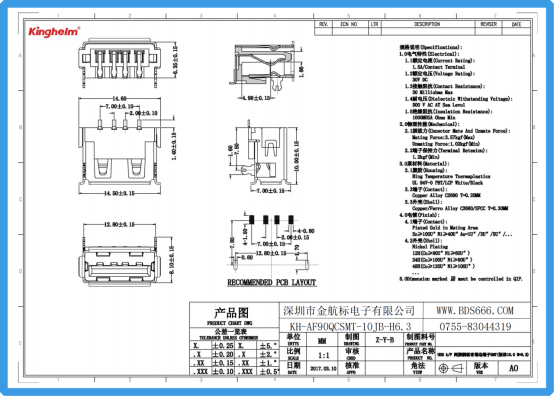

Kinghelm KH-AF90QCSMT-10JB-H6.3 Specificatio

Kinghelm's KH-AF90QCSMT-10JB-H6.3 is more than a connector—it embodies a future-oriented philosophy of high-density interconnection. With its extreme 6.3mm height, space-efficient 90° horizontal mount, SMT-driven manufacturing revolution, and "JB"-version durability commitment, it redefines the value of Type-A interfaces in compact devices. In an era where electronics relentlessly evolve toward "lighter, thinner, faster, stronger," this relentless pursuit of spatial efficiency, manufacturing efficiency, and energy efficiency is the core engine driving technological accessibility. Choosing Kinghelm's solution means gaining market advantage through millimeter-level innovation.

About Kinghelm

Shenzhen Kinghelm Electronics Co., Ltd.(www.kinghelm.net)has technical backbones from Tsinghua University and UESTC, and has introduced overseas returnee professionals. Kinghelm is able to develop highly reliable and high-performance antenna and connector products.KH series products of "Kinghelm" brand include Beidou/GPS antennas, RF adapter connectors, plug connector, electrical data connectors, terminals, and customized vehicle harnesses, industrial / medical connectors, and special antenna connectors."Kinghelm connects world", Kinghelm has grown with the development of China's Beidou industry. Starting from supplying Beidou/GPS dual mode antennas, IPEX terminals, and RF adapter cables for automotive manufacturers, Kinghelm has continuously developed products. Currently, it has a series of WiFi, Bluetooth, NB-loT, LoRa, Zigbee, UWB, and GSM antennas, RFID tags, RF adapter cables, standard microwave antennas, vehicle grade SMA, SMB, FAKRA holders, coaxial cables, and can customize non-standard antenna connectors based on customer drawings or samples.