Service hotline

+86 0755-23615795

Release date:2025-07-14Author source:KinghelmViews:42

In the rapidly evolving landscape of electronics design, the pursuit of lighter, thinner, and more powerful devices has become the dominant trend, inevitably placing dual demands on the spatial footprint and performance of internal components. Faced with the increasingly precious real estate on circuit boards, the challenge of achieving high-performance, highly reliable connections within constrained areas is paramount for engineers. The KH-3.0AF90DIP-14.2JB-STM USB Type-A Surface-Mount Receptacle emerges as a solution precisely engineered to address this core need. It skillfully integrates space conservation with performance assurance, offering a dependable connectivity solution for a wide range of electronic devices, particularly those demanding meticulous space utilization without compromising on functionality.

Kinghelm KH-3.0AF90DIP-14.2JB-STM Product Image

Space optimization stands as one of this connector's most compelling advantages. Its surface-mount technology (SMT) installation method positions the connector body parallel to the PCB surface, significantly reducing the vertical profile perpendicular to the board. This low-profile design is immensely valuable for devices where internal space is extremely precious. For instance, in ultra-thin laptops and tablets, every millimeter shaved off the thickness is critical. In mobile device accessories like portable hard drive enclosures or docking stations, compact layouts are key to enhancing portability. Even in environments such as automotive infotainment systems, USB charging ports, or industrial automation control cabinets—where space is limited or high-density PCB integration is required—the surface-mount design liberates valuable space resources. This grants engineers greater design freedom, enabling the accommodation of more features within smaller volumes or reserving space for critical components like batteries or thermal solutions, thereby optimizing overall device performance and user experience.

Naturally, merely saving space is insufficient; robust connection performance is equally indispensable. The KH-3.0AF90DIP-14.2JB-STM strictly adheres to the USB 3.0 specification and is fully backward compatible with the widely adopted USB 2.0 standard. This means it seamlessly supports theoretical data transfer rates up to 5Gbps (USB 3.0 SuperSpeed). This high-speed capability offers significant advantages when handling HD video, large engineering files, or software installation packages, substantially reducing user wait times and improving workflow efficiency. Its 9-pin contact configuration underpins stable high-speed transmission: 4 pins handle USB 2.0 data (D+, D-) and power (VBUS, GND), while the additional 5 pins are dedicated to the USB 3.0-specific high-speed differential signal pairs (TX+, TX-, RX+, RX-) and enhanced grounding. This design ensures the integrity of data transmission channels and effective isolation between signals. Furthermore, the connector supports a rated current output of 1A (-Power), providing relatively ample and stable power delivery for most common USB peripherals—such as flash drives, portable hard drives, and certain external devices—ensuring their reliable operation.

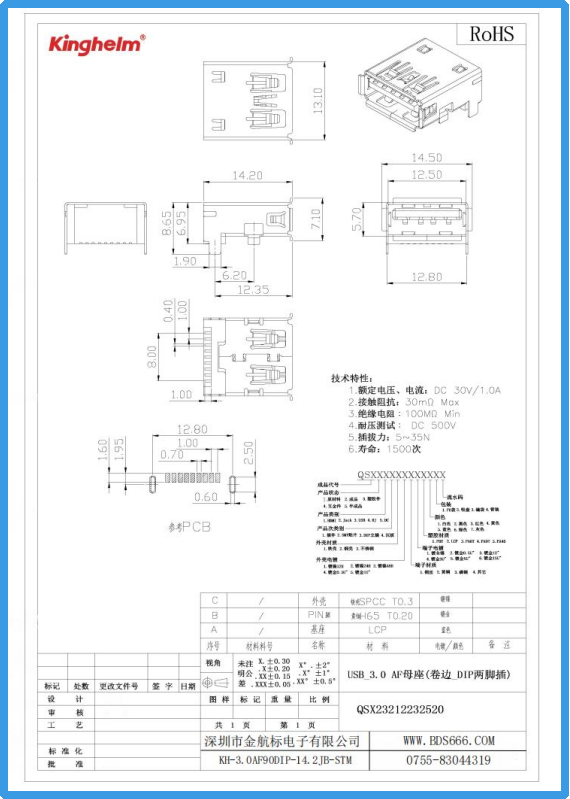

Kinghelm KH-3.0AF90DIP-14.2JB-STM Specification

Manufacturing efficiency and product consistency play pivotal roles in modern electronics production. This model utilizes a standardized DIP (Dual In-line Package) pin layout format. This packaging has a long history and mature specifications within the electronics manufacturing industry, with pin pitch and arrangement conforming to common industry standards. This grants it high compatibility on automated production lines. As a surface-mount (SMT) component, it integrates seamlessly into mainstream SMT production workflows. The standardized DIP packaging greatly facilitates automated equipment (like high-precision pick-and-place machines) in tasks such as recognition, pick-up, positioning, and placement. It simplifies programming, feeder configuration, and changeover processes for key steps like solder paste printing, component placement, and reflow soldering, effectively boosting overall production efficiency (Units Per Hour - UPH). More importantly, the high consistency and repeatable precision achieved through automation are difficult to match with manual operations. Machines ensure every connector is placed onto the corresponding PCB pads with identical position and force, maximizing the elimination of errors and variations potentially introduced by human factors. This high level of consistency during production is fundamental to guaranteeing reliable soldering, stable functionality, and uniform quality in the final product, significantly increasing production yield rates and reducing costs associated with rework and quality control.

Benefiting from its combined strengths—delivering USB 3.0 high-speed data transfer (with USB 2.0 compatibility) within a compact space, providing stable 1A power delivery, featuring a rugged and reliable physical structure, and being compatible with efficient automated production—the KH-3.0AF90DIP-14.2JB-STM demonstrates broad industry applicability. It naturally becomes the ideal USB interface choice for consumer electronics such as ultra-thin laptops, tablets, high-end monitors, smart TVs, gaming consoles, set-top boxes, external storage devices, and multi-port chargers. In the mobile accessories market, it serves as an indispensable connection hub for OTG adapters, smartphone docking stations, power bank output ports, portable speakers, and handheld gimbals requiring reliable USB Host functionality. For audio-visual equipment, high-performance DACs (Digital-to-Analog Converters), professional audio interfaces, video capture cards, and network media players rely on high-speed USB interfaces for transmitting high-fidelity lossless audio or video streams; this connector is well-suited for this critical task. In automotive electronics, facing constraints of limited in-vehicle space and the rigors of temperature and vibration, its compact design and reliability make it a robust choice for USB ports in infotainment systems, rear-seat entertainment systems, and vehicle chargers. Similarly, within industrial control and automation environments, devices like industrial PCs (IPCs), HMIs (Human-Machine Interfaces), PLC programming ports, industrial cameras, data loggers, and test/measurement equipment—which demand exceptional connection stability and durability—can benefit from its rugged construction and the reliability of SMT soldering, ensuring smooth processes for data transfer, firmware updates, and device debugging.

In conclusion, the Kinghelm KH-3.0AF90DIP-14.2JB-STM USB Type-A Surface-Mount Receptacle represents a sophisticated connector solution achieving a delicate balance between spatial constraints and performance requirements. Its innovative surface-mount design effectively addresses the spatial challenges posed by modern electronics miniaturization. Full compliance with the USB 3.0 high-speed standard meets the escalating demands for data transfer. Meticulous material selection and structural design are dedicated to providing a long-lasting and stable connection experience. Furthermore, its standardized packaging aligns with the demands of efficient, automated production. Whether facing the pursuit of extreme thinness in consumer electronics, the need to balance portability and function in mobile accessories, the reliance on high-speed transfer in AV equipment, or the dual trials of space and reliability in automotive and industrial settings, this surface-mount USB receptacle, through its comprehensive performance, offers engineers a mature and trustworthy technological pathway when designing compact devices requiring high-performance USB connectivity.

About Kinghelm

Shenzhen Kinghelm Electronics Co., Ltd.(www.kinghelm.net)has technical backbones from Tsinghua University and UESTC, and has introduced overseas returnee professionals. Kinghelm is able to develop highly reliable and high-performance antenna and connector products.KH series products of "Kinghelm" brand include Beidou/GPS antennas, RF adapter connectors, plug connector, electrical data connectors, terminals, and customized vehicle harnesses, industrial / medical connectors, and special antenna connectors."Kinghelm connects world", Kinghelm has grown with the development of China's Beidou industry. Starting from supplying Beidou/GPS dual mode antennas, IPEX terminals, and RF adapter cables for automotive manufacturers, Kinghelm has continuously developed products. Currently, it has a series of WiFi, Bluetooth, NB-loT, LoRa, Zigbee, UWB, and GSM antennas, RFID tags, RF adapter cables, standard microwave antennas, vehicle grade SMA, SMB, FAKRA holders, coaxial cables, and can customize non-standard antenna connectors based on customer drawings or samples.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853