Service hotline

+86 0755-23615795

Release date:2025-06-11Author source:KinghelmViews:3646

Qtech Technology Co., Ltd Factory in Malaysia

"With manufacturing facing intense competition, where is the way out for domestic processing factories?"

Mr. Deng Liyou's Qtech Technology Co., Ltd has been bustling with production at its Longgang, Shenzhen factory, and recently invested in building a new factory in Malaysia, accelerating its international journey. To explore how this was achieved, the editorial team from Kinghelm (www.kinghelm.net) visited the industrial park to interview Mr. Deng Liyou, Chairman of Qtech Technology Co., Ltd.

Mr. Deng Liyou

70s native of Mianyang, Sichuan, Mr. Deng was an early practitioner of China's street - vendor economy and has long been acquainted with Mr. Song Shiqiang, a well - known "Huaqiangbei street - vendor economist" who also hails from Sichuan and has work in Shenzhen for years. When we first met him, he emerged from the busy workshop wearing a dust - free suit and taking off his mask. While we were amazed by his hands - on approach to ensuring quality by diving into production, we were soon surprised again by his relaxed manner when making tea. This reflects the unique "hard work" and "leisure" of a Sichuan native, as well as the "prominence" and "modesty" rooted in his birthplace, Mianyang, "China's only science and technology city". This seemingly contradictory yet powerful character is truly "comfortable" and "excellent", deeply infectious.

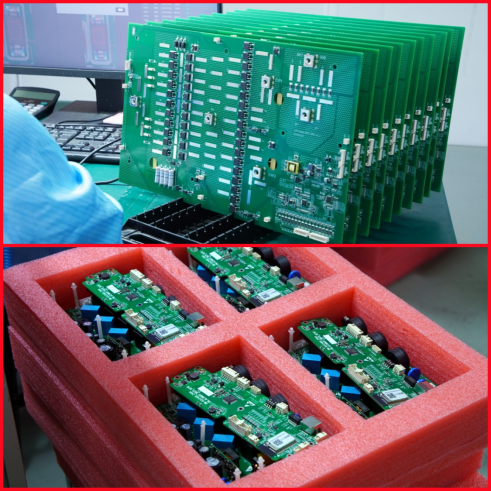

Qtech Technology Co., Ltd Office in China

Mr. Deng emphasized that Qtech's competitiveness stems from refined management. How to accurately grasp the "degree" of factory management? He replied, "Let professionals do professional things and give full play to their expertise." Taking us on a tour of the electronic warehouse, SMT workshop, and DIP workshop, he introduced, "Established in 2014, Qtech Technology Co., Ltd. has over 10 years of production experience serving global customers across multiple industries, including automotive electronics, medical electronics, communication products, industrial automation, and smart home. In particular, its SMT and DIP workshops have introduced a series of advanced processing equipment, such as the GKG (G9 +) solder paste printer, Sinic - Tek online 3D SPI - S8080, Yamaha chip mounters YSM20R and YSM10, JVT 10 - zone reflow oven, Bluiris first - article inspection equipment, Scienscope X - Ray, Zoom XRAY point - counting machine, Nittoku wave soldering machine, and pre - oven AOI Raytron 200 and post - oven final inspection AOI Raytron 500. With equipment investments exceeding ten million yuan, these not only improve production efficiency and optimize processes but also reduce labor costs. That's why you see few production line workers now - there are only over 50 employees in several large workshops. By leveraging machinery and management advantages, Qtech achieves intelligent, lean, and digital management of the entire product lifecycle (from incoming material qualification - warehousing - planning - material production - inspection - delivery), providing one - stop manufacturing services such as SMT material processing, SMT chip processing, PCBA processing, circuit board processing, and DIP plug - in processing. It can deliver large quantities of products on time and with high quality and has obtained ISO9001 quality management system and ISO13485 medical device quality management system certifications."

SMT Workshop

When asked, "As an EMS contract manufacturer, how did Qtech successfully go global?" Mr. Deng's sharing fully demonstrates "Where is the road? The road is beneath our feet", which aligns with Mr. Song Shiqiang's view of the "daring to break new ground" spirit of Huaqiangbei. Mr. Deng pointed out that every international industrial relocation is an excellent opportunity for enterprises to "go global" and explore new frontiers. Those who follow the trend seem to have divine help. The fourth (late 20th to early 21st century) and fifth (since 2012) international industrial relocations have both been led by China, become the "world factory" and "global manufacturing center", as described by Lei Jun as the "wind outlet". Therefore, Qtech, jointly invested by Mr. Deng Liyou and Malaysian Chinese, has deeply cultivated the Chinese market for over 10 years since 2014, accumulating rich experience in localized operations. Now, choosing Malaysia as the layout point for the "China + 1" supply chain strategy is both a "strategic expansion" following the trend and a "historical return" after an expedition. Mr. Deng emphasized that Qtech's new factory project in Malaysia has made new progress. It started preparing by renting a factory building in December 2024, equipment was installed in May 2025, with investments in fully automated equipment exceeding ten million yuan, and formal operation and trial production began in June.

Mr. Song Shiqiang, General Manager of Kinghelm (www.kinghelm.com.cn) and Slkor, said that SMT is a crucial node in the intelligent manufacturing process of electronic products. Qtech, led by Deng Liyou, is a rapidly developing industry rising star trusted by many high - quality customers at home and abroad. Its internationalization can drive the overseas expansion of the semiconductor industry chain and help Kinghelm's RF antenna connectors and Slkor's power devices and analog components enter foreign customers' supply chains, contributing to the international development of China's semiconductor industry!

Yamaha Surface Mounter YSM20R

From the "Made in China 2025" plan to the "new quality productivity" strategy, domestic processing industries face both opportunities and challenges. Mr. Deng said, "Choosing to engage in processing stems from my dream of becoming strong and big, to prove myself and see how far I can go. Now, Qtech's biggest goal is to survive and keep going together with my brothers who have fought alongside me for years. I am confident in the semiconductor industry, and we Chinese are the smartest, hardest - working, and most intelligent people."

GKG G9 SMT Stencil Printer

Here, Kinghelm Company and Mr. Song Shiqiang sincerely wish that under the leadership of Chairman Deng Liyou, Qtech will adhere to self - reliance, continue to strengthen manufacturing, and strive for a bright future for all the brothers and sisters who have struggled together. At the same time, we wish Qtech's new factory in Malaysia a successful opening and great prosperity, to become bigger and stronger and open more factories in the future, making Chinese manufacturing a symbol of international quality standards!

SinicTek S8080 3D Solder Paste Inspection Machine 3D SPI-S8080