Service hotline

+86 0755-23615795

Release date:2025-07-14Author source:KinghelmViews:12

Within modern electronic system architectures, the selection of connectors fundamentally influences overall device reliability and user experience thresholds. The Kinghelm KH-2AF180-10JB USB Type-A dual-port vertical receptacle connector addresses this imperative through a design philosophy balancing mechanical robustness, optimized electrical performance, and environmental resilience. Engineered for high-density connectivity in complex operating environments, this solution demonstrates distinctive value across consumer electronics, industrial automation, and automotive applications where simultaneous multi-device access and sustained operational stability are critical.

The through-hole (DIP) mounting configuration establishes foundational physical reliability. Unlike surface-mount alternatives, its PCB-penetrating pins create a three-dimensional anchoring effect post-soldering, substantially enhancing resistance to shear forces and torsional stress. This mechanical integrity proves indispensable in high-cycle applications—from computer peripherals enduring daily mating operations to automotive infotainment systems absorbing road-induced vibrations. By distributing mechanical stress through increased solder joint depth and contact area, the design mitigates failure risks associated with connector torsion during device insertion or equipment resonance. The through-hole architecture further facilitates prototyping and low-volume manufacturing, enabling rapid design iteration through manual soldering while simplifying circuit validation during development phases.

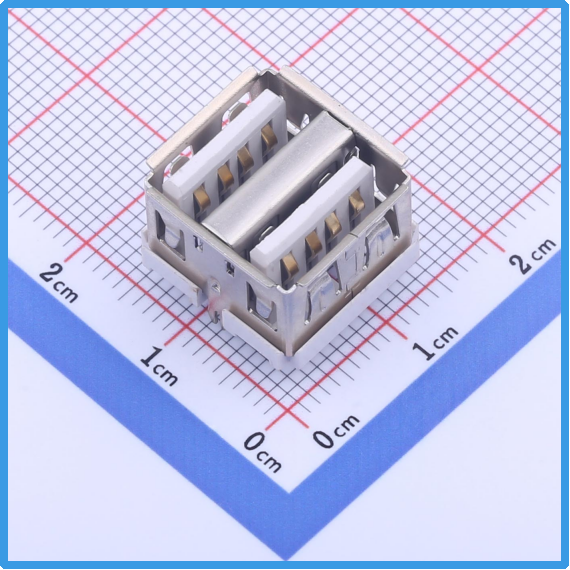

Kinghelm KH-2AF180-10JB Product Image

Integrated dual-port functionality delivers tangible system-level efficiencies. Two standard USB Type-A receptacles arranged in parallel enable concurrent operation of peripheral devices within a single connector footprint. This configuration conserves panel space—reducing enclosure cutout requirements by approximately 30% versus discrete connectors—while streamlining internal cable management. Practical implementations range from industrial control panels hosting barcode scanners alongside environmental sensors to automotive consoles simultaneously supporting navigation storage and mobile device charging. Strict adherence to USB-IF specifications ensures compatibility with the global ecosystem of USB 2.0/1.1 cables, while precisely engineered port spacing prevents physical interference during adjacent device usage.

Electrically, the "4P+4P" contact arrangement provides each port with dedicated VBUS (power), D+ (data+), D- (data-), and GND (ground) pathways. While not specified for USB 3.0, its 480Mbps USB 2.0 High-Speed capability adequately services industrial control programming, medical data logging, and automotive video offloading requirements. The 1.5A cumulative current capacity supports flexible allocation strategies—whether equally distributed or dynamically managed via control circuitry—providing essential headroom for power-intensive peripherals like external drives that may demand 800mA startup surges. Phosphor bronze contacts with optional tin-nickel or hard-gold plating maintain sub-30mΩ contact resistance beyond 5,000 mating cycles, preventing performance degradation from oxidation.

Environmental resilience manifests through an operational temperature range spanning -55℃ to +85℃. This enables reliable functionality in arctic mining equipment cold-starts where conventional plastics become brittle, while high glass-transition-temperature (Tg >120°C) housing materials resist deformation in foundry control cabinets. Engineering-grade thermoplastics like glass-reinforced LCP or PA9T with Comparative Tracking Index (CTI) ratings exceeding 600V prevent electrical tracking in humid conditions. The "JB" designation potentially indicates specialized variants featuring IP67 environmental sealing, MIL-STD-202G vibration certification, or automotive USCAR-30 compliance—capabilities enabling deployment in off-road vehicle powertrain modules or coastal industrial monitoring systems.

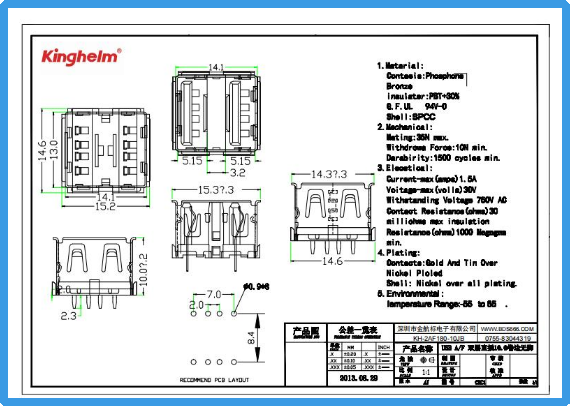

Kinghelm KH-2AF180-10JB Specification

Manufacturing considerations reveal inherent advantages for medium-volume production. Through-hole construction facilitates robust solder fillet formation during wave soldering, yielding joints with 3-5× greater fatigue strength than surface-mount equivalents. This process reduces dependency on precision solder paste deposition equipment while enabling reliable void inspection via X-ray. Industry-standard 2.54mm pin spacing ensures compatibility with automated insertion systems capable of 80-100 units/minute throughput.

Real-world applications validate the connector's multifaceted value proposition: smart home controllers leverage dual ports for concurrent WiFi connectivity and firmware updates; medical diagnostic equipment utilizes hot-swappable redundancy for uninterrupted data recording; electric vehicle charging stations maintain USB functionality at -40℃; and hazardous-environment enclosures incorporate the connector in intrinsically safe designs with current-limiting safeguards.

Underlying electrical integrity is preserved through interference-countermeasures: aluminum-foil-shielded twisted pair wiring minimizes data line crosstalk, while π-filter networks (10μH inductors + 100nF capacitors) suppress power supply noise below 50mVpp. These implementations—combined with shielded metal housings—maintain signal integrity in electromagnetically challenging environments like industrial motor control centers.

The Kinghelm KH-2AF180-10JB ultimately transcends conventional port functionality through synergistic engineering: mechanical anchoring extends service life; dual-port integration redefines connection density; 1.5A power delivery overcomes traditional limitations; and extreme-temperature operation enables global deployment. This convergence of attributes establishes a critical reliability nexus between consumer convenience expectations, automotive environmental demands, and industrial durability requirements—transforming the component into a foundational element of system-level dependability for designs demanding maintenance-free operation under duress.

About Kinghelm

Shenzhen Kinghelm Electronics Co., Ltd.(www.kinghelm.net)has technical backbones from Tsinghua University and UESTC, and has introduced overseas returnee professionals. Kinghelm is able to develop highly reliable and high-performance antenna and connector products.KH series products of "Kinghelm" brand include Beidou/GPS antennas, RF adapter connectors, plug connector, electrical data connectors, terminals, and customized vehicle harnesses, industrial / medical connectors, and special antenna connectors."Kinghelm connects world", Kinghelm has grown with the development of China's Beidou industry. Starting from supplying Beidou/GPS dual mode antennas, IPEX terminals, and RF adapter cables for automotive manufacturers, Kinghelm has continuously developed products. Currently, it has a series of WiFi, Bluetooth, NB-loT, LoRa, Zigbee, UWB, and GSM antennas, RFID tags, RF adapter cables, standard microwave antennas, vehicle grade SMA, SMB, FAKRA holders, coaxial cables, and can customize non-standard antenna connectors based on customer drawings or samples.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853