Service hotline

+86 0755-23615795

Release date:2025-07-11Author source:KinghelmViews:20

In the context of the ongoing trends towards high integration and increasing functional density in modern electronic devices, the choice of internal connectors directly impacts product performance stability, production efficiency, and the end-user experience. The Kinghelm KH-2AF180-10 USB Type-A Dual-Port Vertical Receptacle emerges as a precision interconnect solution born from this very need. It transcends basic connectivity, offering equipment manufacturers a core component that combines high performance, exceptional reliability, and production convenience through a series of deliberate engineering designs and rigorous quality control. Its most distinctive feature lies in the integration of two independent standard USB Type-A receptacles. This design is not merely a physical stacking but a deep understanding of the growing demand for multi-functional interfaces in modern devices. In consumer electronics like smart speakers, multi-port charging docks, or industrial control panels, space is an extremely precious resource. Traditional solutions might require soldering two separate receptacles side-by-side, occupying more PCB real estate, increasing routing complexity, and raising material management and assembly costs. The integrated dual-port design of the Kinghelm KH-2AF180-10 fundamentally optimizes space utilization by condensing two standard USB ports into a compact footprint, significantly reducing PCB layout pressure and providing a solid foundation for device miniaturization and internal structural optimization.

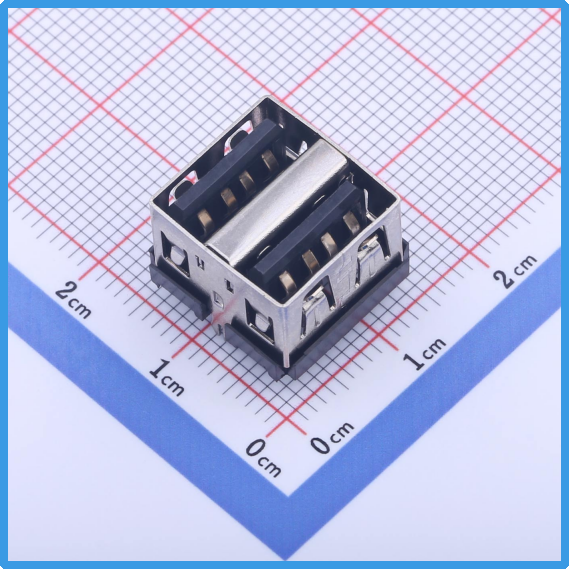

Kinghelm KH-2AF180-10 Product Image

Complementing this compact design is its vertical (Through-Hole) mounting method. In today's era of high-speed automated production, through-hole components (THT) retain irreplaceable advantages over surface-mount technology (SMT) in certain critical scenarios. The vertical pins of the Kinghelm KH-2AF180-10 form stronger mechanical anchoring and more reliable electrical connections during wave soldering or selective soldering processes. Its solder joints typically exhibit superior ability to withstand mechanical stress (such as mating/unmating forces, vibration, shock) compared to pure SMT components. This is particularly crucial for interface products – as the point of frequent user plugging and unplugging, the mechanical stability of the USB port's solder joints on the PCB directly determines the product's long-term durability. Simultaneously, the vertical design simplifies the production flow, reducing complex process arrangements for PCBs using mixed technology (SMT+THT), thereby enhancing production yield and efficiency.

The core mission of this connector is the stable and efficient transmission of signals and power, achieved through its 4P+4P contact configuration where each port independently has 4 contacts, strictly adhering to USB specifications. Its contacts are made from high-quality conductive alloy materials (such as phosphor bronze) and undergo precision plating processes (typically gold or tin plating, ensuring low contact resistance and excellent corrosion resistance). This combination of material and process is key to guaranteeing signal integrity for high-speed data transfer (compatible with USB 2.0 and potentially higher speeds). Low and stable contact resistance minimizes signal attenuation and energy loss, while the quality plating effectively resists oxidation and sulfidation in the environment, maintaining stable electrical performance even during prolonged use or in harsher conditions. Regarding power transmission, each port supports a rated current of up to 1.5A, fully meeting USB specifications for Standard Downstream Ports (SDP) and Charging Downstream Ports (CDP). This is vital for devices requiring reliable power supply to peripherals, such as powering external hard drives, fast-charging mobile devices, or driving USB-powered peripherals like fans. The stable 1.5A power delivery capability ensures connected devices receive sufficient and stable energy, preventing operational anomalies or slow charging due to insufficient power. Its internal structure design also fully considers current-carrying capacity and temperature rise control, ensuring safe and reliable operation even under full load.

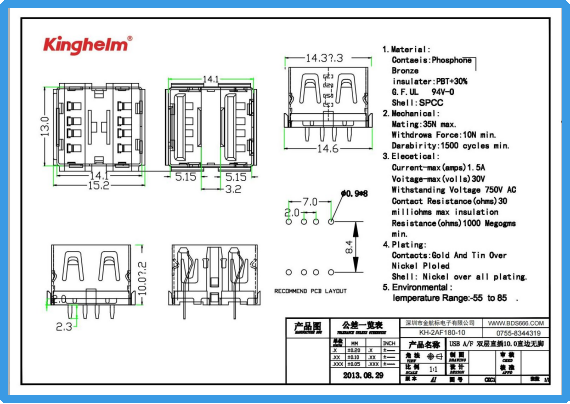

Kinghelm KH-2AF180-10 Specification

Long-term reliable operation is underpinned by comprehensive assurance encompassing material selection, manufacturing processes, and environmental resilience. The housing typically utilizes high-strength engineering plastics (such as PBT, nylon), materials possessing excellent mechanical strength to endure repeated mating/unmating stresses while effectively resisting wear from daily use, chemical solvent erosion, and ultraviolet (UV) degradation, with a flammability rating usually complying with the UL94 V-0 standard. Exquisite manufacturing processes form another pillar of reliability, from precision-stamped metal contacts to injection-molded housings and automated assembly, with each stage implementing strict quality control. Finished products must pass a series of rigorous environmental reliability tests, including mating durability tests (typically tens of thousands of cycles), salt spray testing, high temperature/high humidity testing, and thermal shock testing to ensure stable performance under various stress conditions. Particularly noteworthy is its wide operating temperature range (-55°C to +85°C), a specification that greatly expands its application potential by allowing reliable operation in diverse environments – from the localized high temperatures within densely packed consumer electronics, to the extreme cabin heat of sun-exposed vehicles or freezing winter conditions, and the demanding temperature variations encountered in industrial settings like workshops or cold storage facilities, significantly enhancing the end product's environmental robustness.

Precisely because of its robust physical construction, stable electrical performance, and outstanding environmental adaptability, the KH-2AF180-10 demonstrates immense application potential. It seamlessly integrates into the consumer electronics world, becoming an indispensable standardized data and power gateway in smartphone companions (charging docks, audio DACs), tablet docking stations, digital camera card readers, gaming console peripherals, and smart home hubs. In the computer and peripheral domain, it serves as the foundation for stable connections in desktop and all-in-one PC front panel interfaces, printers, scanners, and keyboard/mouse receivers. Its inherent temperature and vibration resistance make it perfectly suited for automotive applications like In-Vehicle Infotainment (IVI) systems, navigation head units, dashcams, and rear-seat entertainment systems. And in demanding industrial control settings, from PLC Human-Machine Interfaces (HMI) and data export ports on instruments to configuration/update interfaces on automation equipment, its reliability and durability are key factors in ensuring long-term, trouble-free operation. For equipment manufacturers and system integrators, the value is further reflected in significant cost-effectiveness. The standardized Type-A interface ensures plug-and-play compatibility with a vast array of existing USB cables and devices, enhancing user-friendliness. The dual-port design saves PCB space and Bill of Materials (BOM) items, simplifying supply chain management, while the vertical mounting method optimizes production processes, increasing line efficiency and reducing potential defect rates, collectively providing a highly competitive Total Cost of Ownership (TCO).

In conclusion, the Kinghelm KH-2AF180-10 USB Type-A Dual-Port Vertical Receptacle is far more than a simple interface component. It is the crystallization of precision engineering, materials science, rigorous manufacturing processes, and deep market insight. Its innovative dual-port compact design, reliable vertical mounting, excellent electrical performance (high-speed data and stable 1.5A power), robust construction, broad environmental adaptability (-55°C to +85°C), and outstanding cost-effectiveness collectively form its core value in a fiercely competitive market. Whether meeting the ever-evolving innovation demands of consumer electronics, satisfying the stringent environmental tests of automotive electronics, or supporting the extreme reliability requirements of industrial control, the Kinghelm KH-2AF180-10 provides steadfast and reliable connectivity. It serves as a trustworthy cornerstone within the internal interconnect architecture of modern electronic devices, continuously offering solid support for device performance and user experience behind the scenes.

About Kinghelm

Shenzhen Kinghelm Electronics Co., Ltd.(www.kinghelm.net)has technical backbones from Tsinghua University and UESTC, and has introduced overseas returnee professionals. Kinghelm is able to develop highly reliable and high-performance antenna and connector products.KH series products of "Kinghelm" brand include Beidou/GPS antennas, RF adapter connectors, plug connector, electrical data connectors, terminals, and customized vehicle harnesses, industrial / medical connectors, and special antenna connectors."Kinghelm connects world", Kinghelm has grown with the development of China's Beidou industry. Starting from supplying Beidou/GPS dual mode antennas, IPEX terminals, and RF adapter cables for automotive manufacturers, Kinghelm has continuously developed products. Currently, it has a series of WiFi, Bluetooth, NB-loT, LoRa, Zigbee, UWB, and GSM antennas, RFID tags, RF adapter cables, standard microwave antennas, vehicle grade SMA, SMB, FAKRA holders, coaxial cables, and can customize non-standard antenna connectors based on customer drawings or samples.

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853