Service hotline

+86 0755-23615795

Release date:2021-12-28Author source:KinghelmViews:3397

1. Project Overview

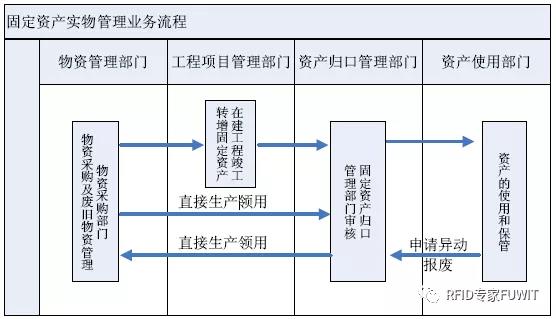

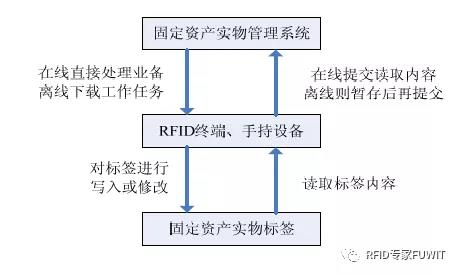

In the enterprise fixed asset management business, fixed assets are directly used by the material procurement department, or transferred to production and operation after the completion of the project to form fixed assets. In-use fixed assets have been replaced by technological upgrading and replaced from one production site to another, and some fixed assets have to be scrapped due to accidents or natural wear and tear. There are many types of fixed asset business subdivisions of enterprises, and rapid technological updates lead to rapid changes in fixed assets. The physical management mode of fixed assets of enterprises is shown in the following figure:

● Registration and inventory work

Fixed assets purchase approval form When purchasing fixed assets, a card account must be registered for each fixed asset, and the serial number, value, and receiving department of the fixed asset must be written in considerable detail, and then registered and kept according to the card account. A uniform number is affixed to each fixed asset to facilitate verification. To depreciate the fixed asset at the end of each month, it is necessary to register the depreciation in the ledger. This kind of work is repetitive and the number of account books is huge. Errors often occur in specific work, and it takes a long time and takes up a lot of staff time. Moreover, manual transcription of physical information and information modification of state changes are weak links to ensure the consistency of "accounts, objects, and cards". Because of this weak link, it will still lead to "account discrepancies", which also restricts the maximum management effect of the management information system.

Second, the application of RFID technology

● Automatic long-distance batch collection of physical information;

● Write the management data information (or inspection records) and the physical information into the electronic label, and the electronic label is installed (pasted) on the physical body;

● According to the physical change information, start the relevant business process to update the equipment (assets) and fixed asset ledgers in real time to ensure that the management data information is consistent with the scene;

RFID is a non-contact automatic identification technology. It automatically identifies the target object and obtains relevant data through radio frequency signals. The identification work does not require manual intervention. The foundation of integrity.

3. System plan

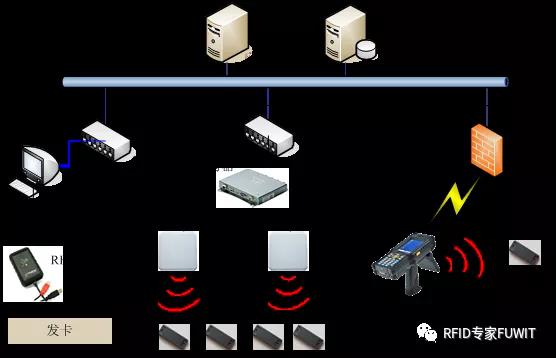

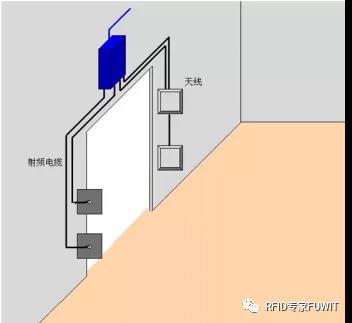

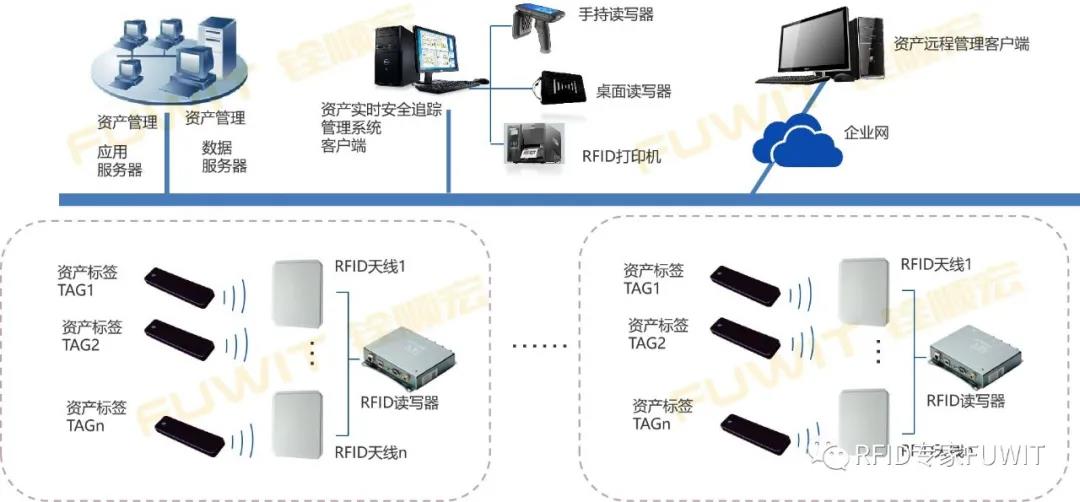

When the fixed asset is in and out of the warehouse, the RFID reader transmits a radio frequency signal through the antenna, and the RFID tag on the asset obtains the induced current, so that the RFID tag acquisition ability is activated and sends its own code and other information to the reader. After receiving the information and uploading it to the asset management application system through the network, the system automatically completes the identification of asset identity and registers asset information, such as asset model, asset number, entry and exit time, handler, approver, etc.; and grasps the flow of assets in real time.

At the same time, the system can also verify the identity and authority of the recipient. When there is a discrepancy, the system will automatically alarm. The system can provide functions such as query, analysis and statistics, and printing, which greatly improves the informatization level of asset management.

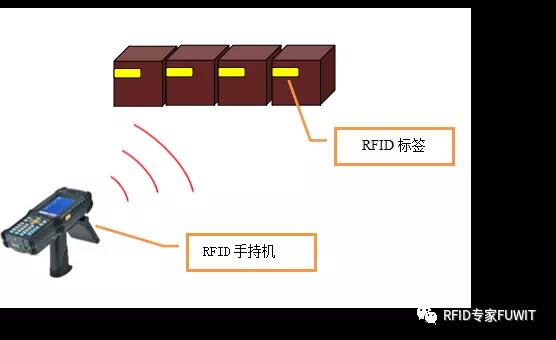

Before inventory, download fixed asset information to handheld RFID device. During the inventory, both misplaced and missing assets are focused on the application. Operators can update inventory count results through the user interface. After the inventory is completed, when the application is connected to the computer network, the data results are uploaded to the RFID system. The working method of inventory is shown in Fig. 3.3.

● Comprehensive query of fixed assets

● System maintenance function

The asset classification code table, exit method code table, purchase method code table, storage place code table, department code table, storage personnel table, and unit name table are listed by the system administrator. Perform operations such as adding, modifying, and deleting.

Provides the operator with the function of modifying his own password.

The system administrator can freely set the operation authority of each subordinate operator to the function.

Provide a variety of safety management means.

Password management function: maintain account and password.

Permission control function: divide users into different levels to determine the user's permission to use the system, and determine different operations according to different permissions.

The introduction of physical information collection tools using RFID technology can effectively solve the bottleneck problem of fixed asset data analysis and collection input and real-time recording of fixed asset actual consumption information. It can truly reflect the actual situation and actual distribution of fixed assets, truly achieve online and visual management, achieve the unification of physical objects and management ledgers, completely realize the unification of accounts, cards and objects, and realize the integrated visual management of physical objects and management systems.

4. System topology

5. System flow chart

6. System function

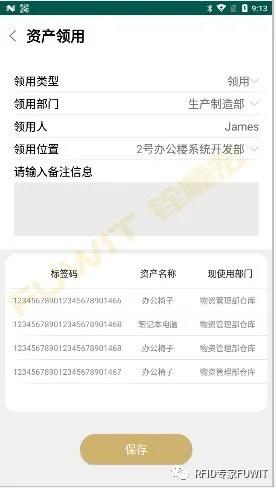

7. Mobile management platform

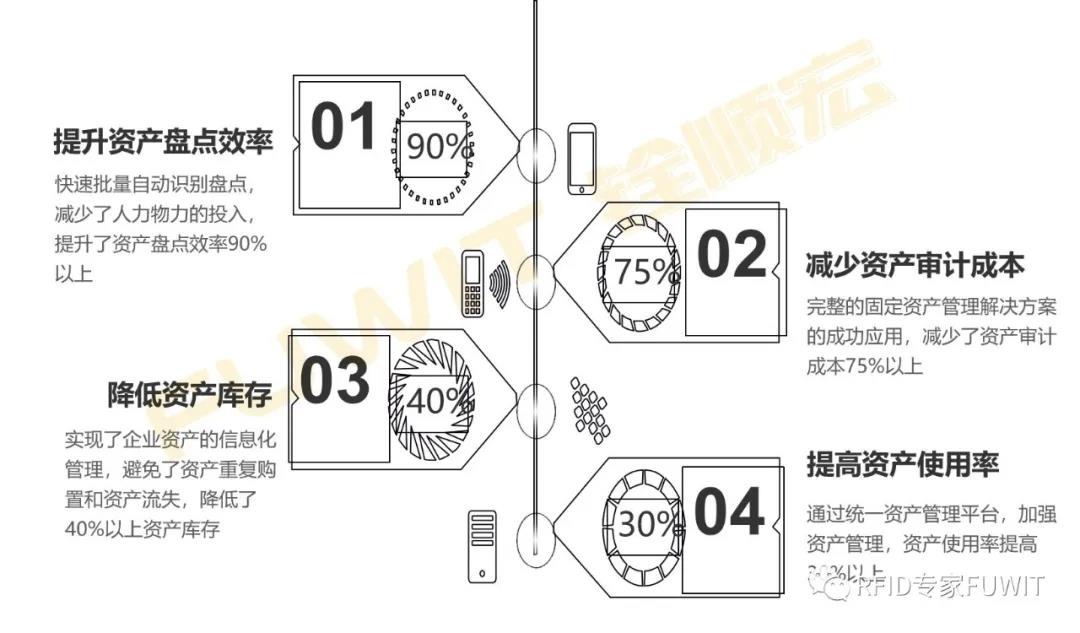

8. Application benefits

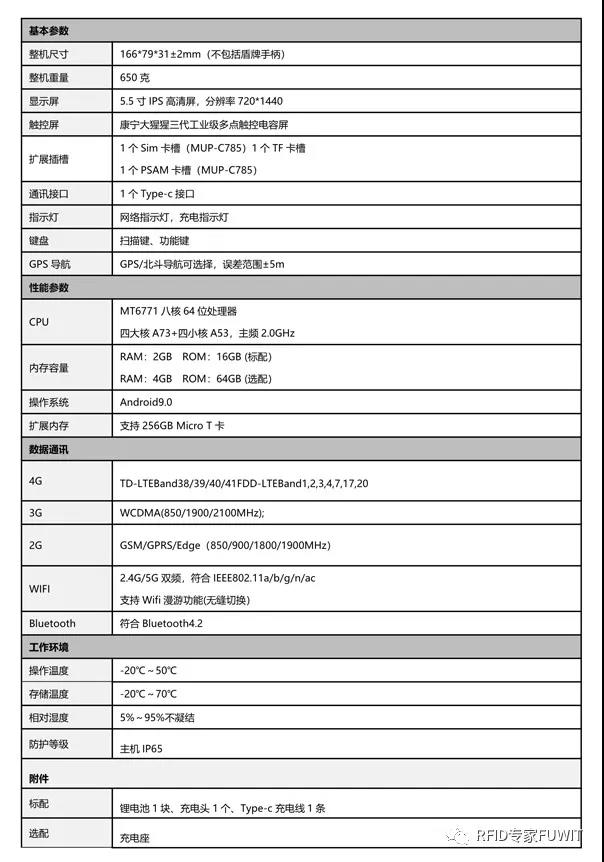

Nine, equipment selection

FU-M6-A is a four-channel UHF RFID reader, which has a high-speed reading capability of 750 tags/second, and can be connected to up to 4 antennas at the same time. Guaranteed not to miss reading. At the same time, FU-M6-A has super anti-interference ability, can adapt to various harsh industrial environments, supports WIFI connection, and can be deployed in key nodes more easily and flexibly.

|

Label Protocol |

EPCglobal Gen 2 (ISO 18000-6C) DRM support; ISO 18000-6B (*optional); I-PX (*optional)

|

|

Antenna Connector |

|

|

RF output |

Independent read and write mode, 5 to 31.5dBm output (1.4W), ± 0.5dBm adjustable |

|

Frequency characteristics |

FCC(NA,SA)902-928MHz;ETSI(EU) 865.6-867.6MHz;MIC(Korea)910-914MHz;SRRC-MII(P.R.China);920-925MHz |

|

Communication Interface |

10/100 Base-T Ethernet; |

|

Wireless network (optional) |

Built-in 802.11 b/g (*optional); |

|

Tag readability |

Greater than 750 tags/sec |

|

Label reading distance |

Greater than 30feet (9 M) with 6dBi antenna (36dBm EIRP) |

|

Maximum read and write EPC ID length |

Up to 496bits |

|

operating system |

Linux kernel version 2.6 |

Handheld devices are mainly used for fixed asset search, inventory and daily business process processing. It involves many functions and has a wide range of applications, which puts forward higher requirements for the RFID reading module in the device.

|

Label Protocol |

EPCglobal Gen 2 (ISO 18000-6C) DRM support; ISO 18000-6B (*optional); I-PX (*optional)

|

|

Antenna Connector |

2 x 50 ohm UFL connected to the edge of the machine or motherboard, supporting 2 independent antennas |

|

RF output |

Independent read and write mode, -5 to 30dBm output, ± 1dBm adjustable |

|

Frequency characteristics |

ETSI (EU, India) 865.6-867.6 MHz;TRAI 865-867 MHz (India);KCC (Korea) 917-920.8 MHz;ACMA (Australia) 920-926 MHz;SRRC-MII (P.R.China) 920-925 MHz;Open (Customizable channel plan;865-868MHz and 902-928 MHz); |

|

Connector |

Stamp hole connector connection mode with 28 pins (including power supply, communication and GPIO) |

|

Communication Interface |

Serial asynchronous communication, 3.3V or 5V logic;

Baud rate 9600-921, 600bps;

USB2.0 hardware interface (up to 12Mbps)

Restart and Shutdown Control

|

|

Tag readability |

Greater than 750 tags/sec; use high performance settings |

|

Label reading distance |

Greater than 30feet (9 M) with 6dBi antenna (36dBm EIRP) |

|

serial number |

Product name |

model |

Function |

quantity |

other |

|

1 |

Fixed reader |

FU-M6-A |

Reader |

1 |

|

|

2 |

RAA915-9R40 |

Reader Antenna |

4 |

||

|

3 |

RF cable |

定制 |

RF cable |

4 |

|

|

4 |

Mobile Handheld Terminal |

W9900X |

mobile job |

1 |

This content comes from network/RFID expert FUWIT. This website only provides reprints. The opinions, positions, technologies, etc. of this article have nothing to do with this website. If there is any infringement, please contact us to delete it!

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853